Red blood cells: Hemolysis

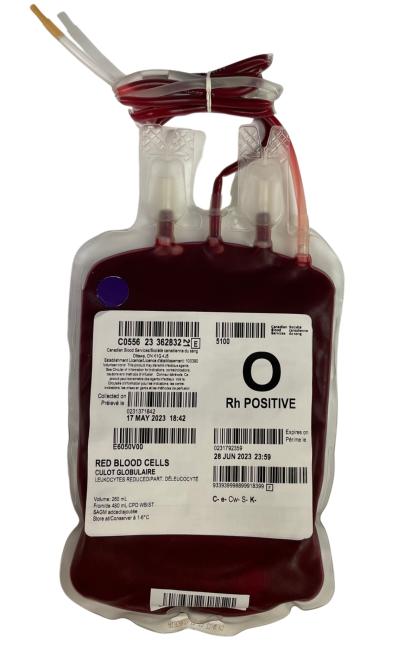

Hemolysis is the breakdown of RBCs and the subsequent release of intracellular contents into the supernatant. The release of hemoglobin, pigmented protein in RBCs, has an important influence on the appearance of RBC units and segments. Hemolysis of stored RBCs is a normal process and increases with storage times. Some degree of hemolysis is acceptable and expected.

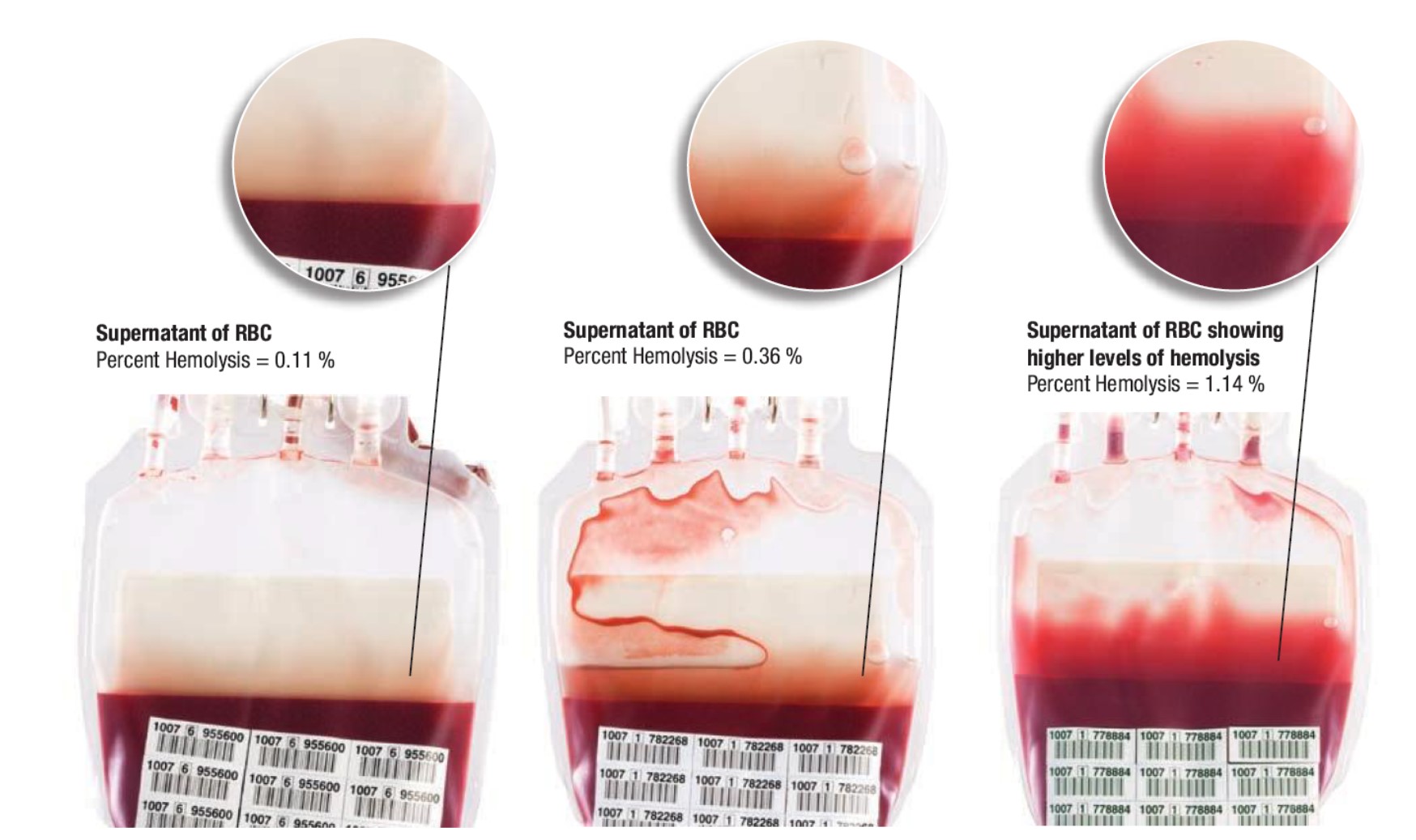

The CSA Standards define unacceptable hemolysis as ≥ 0.8% of red cell mass in 90% of units tested at expiry. However, visual assessment of supernatant colour is the only non-destructive means to estimate hemolysis in a red cell unit. Assessing the supernatant colour is very subjective and it is difficult to define a “cut-off” colour for determining a unit’s acceptability. Supernatant colour estimates supernatant hemoglobin concentration; however, a unit’s percent hemolysis value is also influenced by factors other than supernatant hemoglobin concentration such as hematocrit and total hemoglobin. For example, an increase in hematocrit and/or total hemoglobin will result in a lower percent hemolysis when the supernatant hemoglobin is held constant. The supernatant hemoglobin concentration is therefore only one of the factors that should be considered when determining the percent hemolysis of an RBC unit.

![Percent hemolysis equals [(100 - hematocrit) x supernatant hemoglobin (g/L)] divided by total hemoglobin (g/L)](/sites/default/files/2024-01/Fig1_Hemolysis%20calculation.jpg)

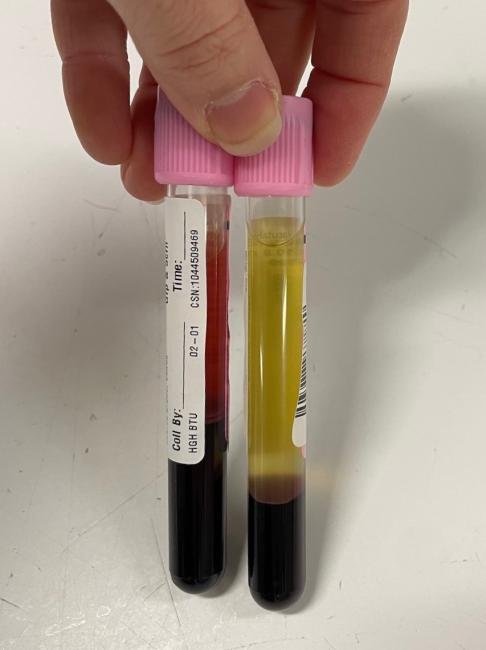

The presence of RBCs in the supernatant may be mistaken for hemolysis. If hemolysis is suspected, it may be worthwhile to allow the unit to settle for 24 hours or more to minimize RBC contamination of the supernatant prior to inspection for hemolysis.

There are many causes of hemolysis; some relate to the manufacturing process and subsequent handling of RBC units:

- Temperature extremes

- Product processing

- Bacterial contamination

- Mishandling

- Incompatible solutions

Visual appearance

- The loss of intact RBCs may result in a lower hematocrit and a brighter red colour.

- Hemolysis caused by bacterial contamination may result in a dark purple to black discolouration (see section on bacterial contamination).

- Free hemoglobin within the supernatant of RBCs will cause a discolouration that will vary from a light pink tinge to a dark red almost purple colour, depending on the extent of hemolysis (i.e., a higher degree of hemolysis will result in a darker discolouration).

- Note that segments do not accurately reflect hemolysis in the unit and should not be used to assess for hemolysis.